One of the most common questions we receive at CO2Meter.com, is "What is the best CO2 controller for my grow space?"

Since being an indoor grower can often bring along some "growing pains," to better assist our customers the team at CO2Meter decided to do the research for them.

After consulting with a handful of growers, vertical farmers, and cultivators, we chose the top 5 grow controllers that are most sought after in this industry.

What is a CO2 Grow Controller?

To grow plants or cannabis, professionally, you may require a fully automatic CO2 generator. You can optionally choose CO2 bags or buckets, but for mid-large grow rooms CO2 generators are really essential in extending your yield and with that comes the need for a means to control the CO2.

Because CO2 regulators just release the CO2 for your plants to grow, it's important to monitor levels over 1,500 ppm as this level starts to become toxic for your plants, thus, we need a controlled solution.

That solution is a CO2 grow controller.

What to look for in a High-Quality CO2 Grow Controller?

When choosing a CO2 grow controller for your indoor grow room, it’s important to focus on functionality, accuracy, and ease of integration with your overall grow system. Whether you're cultivating cannabis, leafy greens, or specialty crops, the right controller can significantly improve yields and efficiency by maintaining the perfect environment for plant growth.

Before purchasing a CO2 grow controller, consider the following key features:

- Integrated CO2 Monitoring – look for built-in (NDIR) sensors for accurate reading

- Configurable Settings– ensures the unit allows you to customize CO2 levels

- Built-In Solenoid Valve - provides automatic CO2 delivery control

- Temperature and Humidity Compatibility – look for this combo for stability

- Large, Easy-to-Read Display – a clear interface will verify conditions

- Calibration Options – look for a controller with manual or automatic calibration

What are the best CO2 grow controllers?

1. Indoor CO2 Controller for Grow Rooms

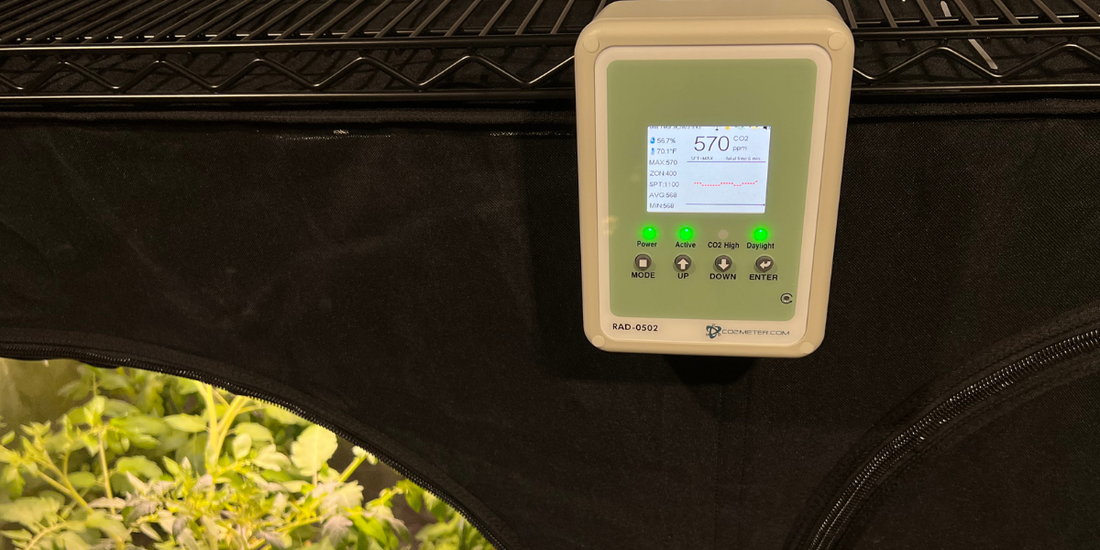

The Indoor CO2 Controller for Grow Rooms is an easy to use solution to adjust, control, and review CO2 levels for one or two grow spaces.

The Indoor CO2 Controller for Grow Rooms is an easy to use solution to adjust, control, and review CO2 levels for one or two grow spaces.

This device allows growers to not only monitor CO2 concentrations and adjust levels as needed with add-on digital regulators, but can monitor 2 zones with 2 individual sensors. In addition, it has the ability to monitor temperature, humidity, and light settings for a the grower. This controller also is pre-wired and plug-and-play ready, making it easy to begin controlling CO2 levels right out of the box.

Additionally, the RAD-0502 also includes a built-in solenoid valve, which is critical for automating CO2 enrichment, ensuring safe and efficient gas delivery and providing a fail-safe shutoff in the event of a power loss or low CO2 demand.

The RAD-0502 is $251.90.

|

Pros:

|

Cons:

|

2. GROZONE Dual Zone CO2 Controller

The Grozone Dual Zone CO2 Controller is used to control CO2 levels in grow rooms as an alternative to CO2 supplementation in indoor agriculture applications.

This CO2 controller also includes a photocell which allows you to have day and night settings as well as activate a trigger based on a co2 generator or regulator.

In addition to its prominent place in the industry, this controller also used nondispersive infrared sensing at its core for accurate and precise measurements,

The device costs $599-$949 depending on where purchased.

|

Pros:

|

Cons:

|

3. Titan Controls Atlas 8

Third on our list, is the Titan Controls Atlas 8.

This device is well-known throughout the agriculture space due to its easy-to-use and robust CO2 grow control ability. Although at a higher price point, the Atlas 8 can monitor, control, and adjust CO2 levels to ensure optimal dispersion and maximum yields.

Another common CO2 control feature for the Atlas 8 is its ability to control tanks, regulators, or CO2 generators. It is also built to withstand harsh conditions. Many growers rely on this device for its fuzzy logic hysteresis which applies constant calculations to the output control for your CO2 regulator to ensure you do not go over your predefined set point.

The Titan retails for $829 on their website.

|

Pros:

|

Cons:

|

4. Iponic Environment 624 Two Zone Grow Controller

Fourth on our CO2 controller list is the Iponic Environment 624 Two-Zone Grow Controller.

This is another ideal choice for CO2 grow control that also allows dual zone monitoring and enables growers to control their grow space with cloud-based access from a PC or smartphone. In addition, this device also can monitor temperature, humidity, central air conditioning, and light settings.

With the Iponic, growers can additionally gain ability to adjust and configure any of the CO2 level set points dependent upon overall preference.

The iPonic list price is $2,449.

|

Pros:

|

Cons:

|

5. TrolMaster Hydro-X Control System with 3-in-1 Sensors

The TrolMaster Hydro-X Control System is recognized throughout the grow space for its professional-grade single zone control capabilities. It is designed for growers who need a more customized or modular CO2 control approach.

The TrolMaster provides the ability to control CO2, temperature, humidity, or light settings in the grow space. However, due to its modular design you need to purchase each sensor and control component separately. it can achieve optimal grow production - you just have to know exactly what you're looking for.

The Hydro-X basic control is $319 with a single temperature/humidity sensor.

|

Pros:

|

Cons:

|

Why Add CO2 to your grow space?

Using CO2 for grow tents and grow rooms is a more advanced technique that can lead to substantial growth. But, this strategy is not for everyone and there can be some other factors at play. By introducing additional CO2 to your indoor grow space it not only is incredibly beneficial for your plants, but also can streamline your production, and is simple.

With the right preparation and an hour or two of free time, you can easily set up a system in your grow space to introduce supplemental CO2 at the right time and add a CO2 grow controller to monitor the space.

Here are a few different methods of adding CO2:

1. CO2 Tanks with Solenoid Regulators - best for grow tents

The most common method of introducing extra CO2 to a grow space for home growers is a standard tank and solenoid regulator. For perspective, a carbon dioxide (CO2) cylinder is usually either 25 or 50 pounds and made of aluminum. This cylinder is filled with compressed CO2 and can also be placed outside the grow tent to save space. Cylinders can are then connected to a solenoid valve-regulator, which is then connected to the controller to regulate the CO2 flow.

When using a solenoid regulator the grower can control the flow of carbon dioxide as it being dispersed from the cylinder. This also helps validate that enough CO2 is going to be released to make an impact on the plants and that there is no excess CO2 leaked.

2. CO2 Generators - optimal for grow room spaces

Not always a very popular choice, but utilized often is creating CO2 by using a CO2 generator or burner. These are also housed in a distinct case that is typically hung from the ceiling of any grow space to be above the canopy of the crops.

Next, a tank of liquid propane or natural gas is connected to the regulator, which is then plugged into a CO2 grow controller. And, as the gas is released into the generator, the burners spark and your carbon dioxide is then produced.

One issue with generators or burners is that they also create carbon monoxide through the burning of the fuel (like your car or furnace). The carbon monoxide will also be absorbed by the plants and can create off flavoring. Also note, that using this method will require the grower to install a carbon monoxide safety system as well to account for this potentially hazardous gas.

Why use a CO2 Grow Controller?

The reason many indoor growers rely on CO2 controllers is because of what happens if you do not monitor and control the CO2 in your space. The right amount of carbon dioxide (CO2) is a terrific means of maximizing crop growth, but, when you release too much of it, this can be detrimental and actually kill your crops.

Another common challenge is in trying to time the release of CO2 to your plants. If done incorrectly it can be very expensive. You'll note we don't list "time release" devices in this article for this very reason.

With a CO2 grow controller you can continuously monitor the total CO2 concentration present in the grow space and shut off any connected CO2 producing equipment (generators or tanks) when the ideal CO2 level is reached. This can also be critical as carbon dioxide tends to only be needed during the photosynthesis period of a plants life cycle, around daylight hours.

How to use a CO2 Grow Controller?

With all the products, it's important to recognize the best from the worst. And, ensure you are getting the best device for a good price.

However, once all is said and done and you have chosen your grow controller, it's important to know how to operate it.

In fact, understanding a few common procedures is critical to creating a great grow space and monitoring your crops to the best of your ability.

Here's a few helpful hints:

- What's the installation process look like, will I need an electrician, installer, or can I set this up myself?

- Does the controller offer plug-and-play capabilities or specific wiring or hardware instructions?

- Can the device be installed into a standard wall outlet, and if international, do I have a separate power supply for my space?

- If using a CO2 generator or burner, consider carbon monoxide production as an issue for you and your plants

- If wireless connectivity is an option, ensure your other growers can access the app or internet to adjust as needed

Just like the importance of any CO2 cylinder, tank, or generator - creating a perfect and consistent flow of CO2 eliminates any errors and generates maximum growing potential.

That being said, a CO2 grow controller can do the hard work for you.

Although most professional growers have their own precise "recipe" for CO2 levels, as a rule of thumb, it is best to keep your CO2 levels between 800 and 1,500 ppm for optimal growth.

How to prevent your CO2 from harming your plants?

If you notice your plants get weak or yellowish in color, then stop using CO2 immediately and try to figure out what’s going wrong. Either too much CO2 is accumulating or the temperature is most likely not appropriate.

CO2 should fall below the cannabis plants because it is a heavy gas that will tend to sink to the ground. Using fans will be helpful to move the CO2 around the room and for the plants to absorb it properly. If you do it properly, your harvest will be ready a few days earlier and you’ll get a much higher yield and productivity.

However, when it comes to those working around CO2 at levels above 3000 ppm it starts to become dangerous for humans to breath and over 5000 ppm it is considered to be fatal.

Understanding CO2 Safety in the Grow Room

Aside from the importance of using a CO2 grow controller in your space, understanding CO2 safety is also critical. For growers working around carbon dioxide, being exposed to high levels of the inert gas can not only be hazardous but sometimes fatal.

This is why it's important to ensure that you have a CO2 safety monitor to enable you to be alerted should CO2 levels exceed safety threshold or a leak occur.

This in turn, will not only save you money but will save your life. And, it is always a good idea to have a safeguard in place for your grow space to better prepare for the "worst case scenario".

We recommend to always invest in an affordable CO2 safety monitor, like the Remote CO2 Storage Safety 3 Alarm that can easily be plugged in near your CO2 source and ensure individual and grow room protection.

For more information regarding gas detection safety or grow control solutions for your grow space, contact us online today