Food Storage

Our food storage CO2 and O2 monitors are accurate, easy to use, and are designed to ensure food quality and reduce food spoilage.

- Most CO2 and O2 analyzers offer push-to-start capabilities

- Allows easy detection of CO2 and O2 gases produced by insects/mold

- Mitigate bacteria growth and lower the pH of preserved food

- Keep food storage fresh and prevent any food-borne illnesses

Using CO2 and O2 Analyzers to Detect Food Spoilage

CO2 and O2 analyzers can be used for early detection of spoilage in food storage, grain silos and modified atmosphere packaging (MAP) to monitor the quality of food. For those in safe grain storage, this application usually results in the need for ensuring CO2 concentrations below 600 ppm, while concentrations of 600-1500 ppm indicate the potential for mold growth. when CO2 concentrations shoot above 1500 ppm severe infestations can be present, making analyzing gases critical to prevent food-borne illnesses. Learn more about gas monitoring in food storage applications, here.

Optimize Food Storage Safety with CO2 Monitoring Solutions

- Mitigate loss of flavor, loss of color, and microbial spoilage in foods

- Gain higher quality stored grain, and lower mycotoxin levels

- Improve shelf-life of fresh foods like meat, fish, vegetables, fruits

- Save millions of dollars in grain production and food storage

Research by Purdue University has confirmed that high CO2 levels detected by stationary and portable devices are associated with high levels of spoilage and the presence of mycotoxins. Furthermore, they compared the ability of temperature sensors and CO2 sensors in a storage unit filled with grain to detect the presence of ‘hot spots’ created to mitigate mold growth and ensure optimal grain quality for consumers.

-

Handheld

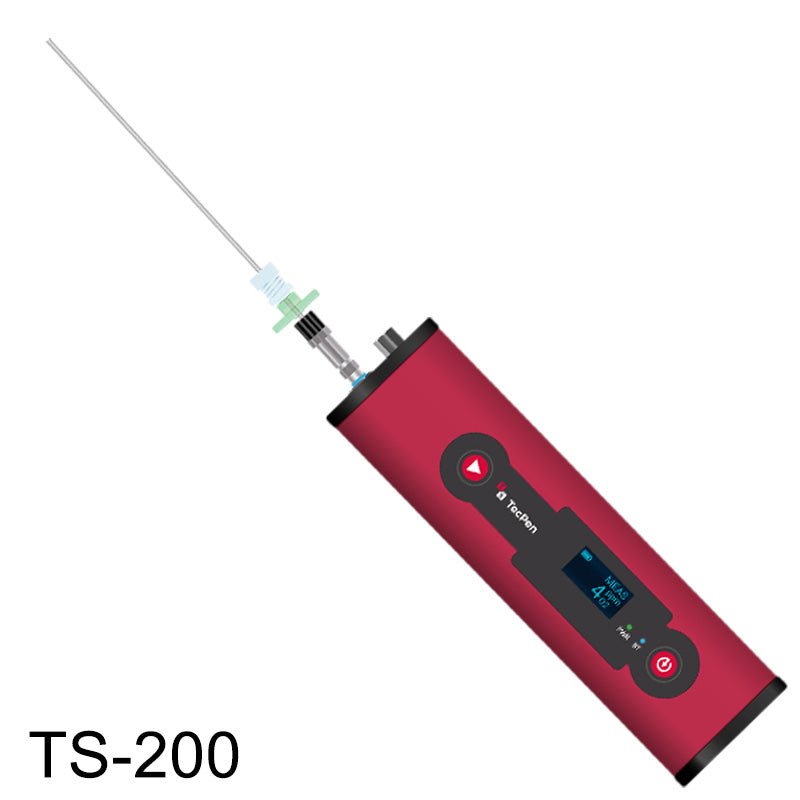

TecPen MAP Oxygen Analyzer

The TecPen MAP Oxygen Analyzer is designed to provide accurate measurements of oxygen content in all closed and pierce-able food packaging,...

$4,234.00 USD$4,234.00 USD$4,234.00 USD -

The Tecpen MAP Oxygen and Carbon Dioxide Analyzer ensures accurate oxygen and carbon dioxide gas level measurements in pierceable, shrink-wrapped packaging....

$5,928.00 USD$5,928.00 USD$5,928.00 USD -

Handheld

Portable 5% CO2 Safety Detector

The PRO-10: Portable 5% CO2 Safety Detector is designed for employees who work in enclosed areas where carbon dioxide buildup may...

5.0 / 5.0

(3) ( 3 )

$399.00 USD$399.00 USD$399.00 USD -

Handheld

Portable CO2 Detector and Alarm

The Portable CO2 Detector and Alarm is a handheld gas detector and data logger designed to measure concentrations in real-time with audible indication. Features...

4.33 / 5.0

(9) ( 9 )

$419.00 USD$419.00 USD$419.00 USD -

Select optionssensors

SprintIR®-6S-100 100% CO2 Sensor

The SprintIR®-6S-100 100% CO2 Sensor (formerly known as the GC-0030) is a high-speed CO2 sensor that can take up to 20...

4.0 / 5.0

(1) ( 1 )

$286.00 USD $399.00 USD$286.00 USD$286.00 USD $399.00 USD -

sensors

SprintIR®-W 100% CO2 Sensor

The SprintIR®-W Carbon Dioxide Sensor is ideal for high-speed sensing requirements and measuring rapidly changing CO2 levels up to 100%. This...

5.0 / 5.0

(3) ( 3 )

$333.00 USD$333.00 USD$333.00 USD -

fixed/wall mount

Oxygen Deficiency Depletion Safety Alarm

The Oxygen Deficiency Depletion Safety Alarm and Horn Strobes (formerly known as the RAD-0002-ZR) is a 0-23% room oxygen monitor designed...

$1,649.00 USD$1,649.00 USD$1,649.00 USD -

fixed/wall mount

Single Sensor O2 Deficiency Monitoring System and Horn Strobe

The Single Sensor O2 Deficiency Monitoring System and Horn Strobe (RAD-SEU-ZR-HS1) includes CO2Meter’s remote oxygen deficiency sensor unit (no remote display)...

$1,029.00 USD$1,029.00 USD$1,029.00 USD -

fixed/wall mount

Complete O2 Deficiency Safety Monitoring Kit

The Complete O2 Deficiency Safety Monitoring Kit is a fully integrated O2 safety monitoring solution designed to detect hazardous oxygen, argon,...

$1,829.00 USD$1,829.00 USD$1,829.00 USD

Don't Take Our Word for it, Take Theirs

Matthew Weintraub

Plant Manager

"Your solutions meet the code requirements and because of you our facility is much safer."

Angela Ihrig

Supply Chain Manager

"CO2Meter has helped protect 150+ of our customers sites and ensure they are compliant and safe."

Michael Hudkins, CFPS

Fire Plans Examiner/Fire Inspector II

"I would recommend CO2Meter gas training to anyone, it inspired us to be keenly aware of what to inspect."

Keith Isoldi

Chief Operating Officer

"I have always worked with CO2Meter because they are the industry leader."

Kelly Kissock

Faculty Director

"Easy to install, Our CO2 tank gassed off and the meter near it worked perfectly!"

Stay Informed with Our Latest Updates

Subscribe to our newsletter for the latest news, product updates, and industry insights.

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO