An oxygen depletion or oxygen deficiency monitor constantly monitors oxygen levels in a room and warns occupants of low oxygen levels.

- Oxygen depletion alarms are wall mounted near stored gases like nitrogen, helium and argon.

- If one of the stored gases is released or inadvertently leaks into the air, the oxygen sensor detects the low oxygen level and displays it on the monitor.

- If the oxygen level is too low it automatically activates an alarm to warn the occupants of oxygen deficiency in the room.

- In some applications an oxygen deficiency monitor can also act as a room air controller, switching on fans to bring in fresh air.

Room oxygen depletion alarms or oxygen deficiency monitors are critical in any room or enclosed area in which low oxygen levels can occur.

Room Oxygen Safety Systems

All living things require oxygen. While too much oxygen can be tolerated for short periods of time, low oxygen levels can lead to death in minutes.

The effects of oxygen deprivation are well known. Within seconds after oxygen ceases to enter the lungs, hypoxemia (low oxygen in blood) and hypoxia (low oxygen in tissues) begins to occur.

The most immediate problem occurs in the brain. Within seconds hypoxemia results in confusion followed by unconsciousness. Irreversible damage to the brain begins in minutes.

Oxygen deprivation as the result of suffocation is a real issue, especially for children. According to a study published by the US National Library of Medicine, about half of the sample who were injured from suffocation were children, who also had higher mortality rates than the general population.

Best practices for reducing the chance for suffocation include removing doors from old refrigerators, removing access to items like toys or plastic bags, and careful supervision in the water or when bathing. Sudden Infant Death Syndrome (SIDS) has also been linked to suffocation. This website from the National Institute of Health has several recommendations for reducing accidental suffocation or strangulation in bed.

Normal Oxygen Levels in Air

By volume, atmospheric air contains 78.09% nitrogen, 20.95% oxygen 0.93% argon, 0.04% carbon dioxide, and small amounts of other gases.

At normal temperatures and pressures, 20.9% oxygen in the air is considered optimal for humans. When oxygen levels drop below 19.5% hypoxia (lowered oxygen levels) begins to occur. The air is considered oxygen-deficient, although it is still relatively safe for short periods of time or for people who have acclimated their bodies to lower oxygen levels.

Why are Oxygen Deficiency Monitors Important?

Oxygen deficient atmospheres are dangerous for human life. The challenge is that the difference between 16% and 21% oxygen is typically made up of inert, invisible and odorless gases like nitrogen, argon or carbon dioxide, so the oxygen deficiency may not be noticed immediately. If oxygen levels remain low, sudden unconsciousness or death without symptoms may occur.

What are the alarm levels for Oxygen Depletion?

Oxygen deficiency monitors will go into alarm mode at readings below 19.5%. This enables audible/visual alarms to indicate to personnel that an action needs to be taken prior to injury.

Humans will not detect ill effects for short duration exposures until oxygen levels reach 14-16 %, but caution is required. If an oxygen deficiency monitor detects levels at or below 14% an extreme emergency condition exists.

What are Oxygen Depletion Alarms set to Trigger at?

Most oxygen depletion alarms are set to give a first warning alarm when it senses oxygen below 19.5%. Subsequent alarm levels can be sent depending on the users or local jurisdictions requirements. Devices should allow for end user configuration of alarm levels to meet their specific needs. These alarms enable action to be taken before an evacuation is required or before a potential incident occurs.

Where are Oxygen Deficiency Monitors Used?

Oxygen depletion alarms are used in any place where low oxygen levels can occur. While most people think of a closed environment like an airplane or submarine, a much more common example is a room where pressurized cylinders of hydrogen, helium, argon, or nitrogen are stored. If a hose or fitting leaks, the depressurization of the gas storage system can rapidly lower the oxygen level in the room.

Examples of stored gases where oxygen depletion alarms are necessary include:

- Nitrous oxide used in hospitals

- Nitrogen used in draft beer dispensing

- Liquid helium to cool MRI machines

- Liquid nitrogen, helium or argon for cryobiology, IVF, cryosurgery or other types of cryogenic research

- Liquid nitrogen to package meats, fruits, or dairy

- Argon or other shield gases for welding

- Nitrogen and argon used in 3D printing

- Argon or other inert gases for fire suppression

While carbon dioxide could be added to this list, common practice is to use a CO2 Safety Alarm to measure high CO2 levels instead of an oxygen deficiency alarm. This is because studies show that even in the presence of normal concentrations of oxygen, exposure to 5% CO2 can cause fatality in just minutes.

In addition, carbon dioxide is heavier than air but oxygen is not. While CO2 tends to lay low to the ground, oxygen is evenly dispersed. This means that in an enclosed workplace the level of concentration relative to oxygen could be significantly different dependent upon where you measure. Further, an oxygen monitor could give you a different result depending on where it is installed.

Reliance on monitoring oxygen levels to protect against a rise in carbon dioxide levels has led to many incidents where further education and proper monitoring could have saved lives.

What are the OSHA requirements for oxygen deficiency monitoring?

The Occupational Safety and Health Administration (OSHA) in the United States has specific guidelines related to the presence of oxygen in the workplace, as insufficient or excess levels of oxygen can pose serious health and safety risks. Below are key OSHA guidelines related to oxygen:

General Industry Standards:

- 29 CFR 1910.134: OSHA's respiratory protection standard (29 CFR 1910.134) outlines requirements for the protection of workers from respiratory hazards, including those related to oxygen deficiency or enrichment.

-

Minimum Safe Oxygen Level:

- OSHA defines the minimum acceptable oxygen concentration in the workplace as 19.5% for general industry. If the oxygen level falls below this threshold, it is considered an oxygen-deficient atmosphere.

- Oxygen-Enriched Atmospheres:

- OSHA also provides guidelines for oxygen-enriched atmospheres, where the oxygen concentration exceeds 23.5%. Environments with elevated oxygen levels can increase the risk of combustion and fire hazards.

Monitoring and Measurement:

- Atmospheric Testing:

- Employers are required to monitor and test the atmosphere in workspaces where employees may be exposed to oxygen-deficient or oxygen-enriched conditions. This testing is particularly important in confined spaces.

- Continuous Monitoring:

- Continuous monitoring may be necessary in situations where the oxygen concentration can fluctuate, ensuring that employees are not exposed to unsafe conditions.

- Confined Space Entry:

- OSHA's 29 CFR 1910.146, "Permit Required Confined Spaces," contains the requirements for practices and procedures to protect employees related to confined space entry, including requirements for testing and monitoring oxygen levels. Confined spaces with potential oxygen hazards must be identified, and proper safety measures must be implemented

Further, an oxygen depletion monitor should have warning levels set according to these oxygen concentration levels.

NIH Oxygen Monitoring Devices Protocols

While not law or an OSHA regulation, the National Institutes of Health Protocol for use and maintenance of Oxygen Monitoring Devices has been established to provide guidance on the installation, maintenance, and calibration of oxygen monitoring devices in animal and laboratory areas in all NIH owned and leased buildings. It states:

"An oxygen monitoring device shall be installed in any indoor location where compressed gases or cryogenic liquids are stored and/or dispensed in manner that could create the potential for the displacement of oxygen. At a minimum, the following factors should be used in determining if a device should be installed: manufacturer (e.g., magnet) guidance, volume of gas used, location of gas, and air changes/hour in the room/area. The 2008 NIH DRM notes that both ‘carbon dioxide manifold rooms… [and] nitrogen holding rooms and shall include oxygen level monitoring alarms’ (section 8, pages 8-80). Additionally, compressed gases or cryogenic liquids shall not be located or dispensed in any indoor location that does not have proper ventilation.

Where Should Oxygen Depletion Alarms be Mounted?

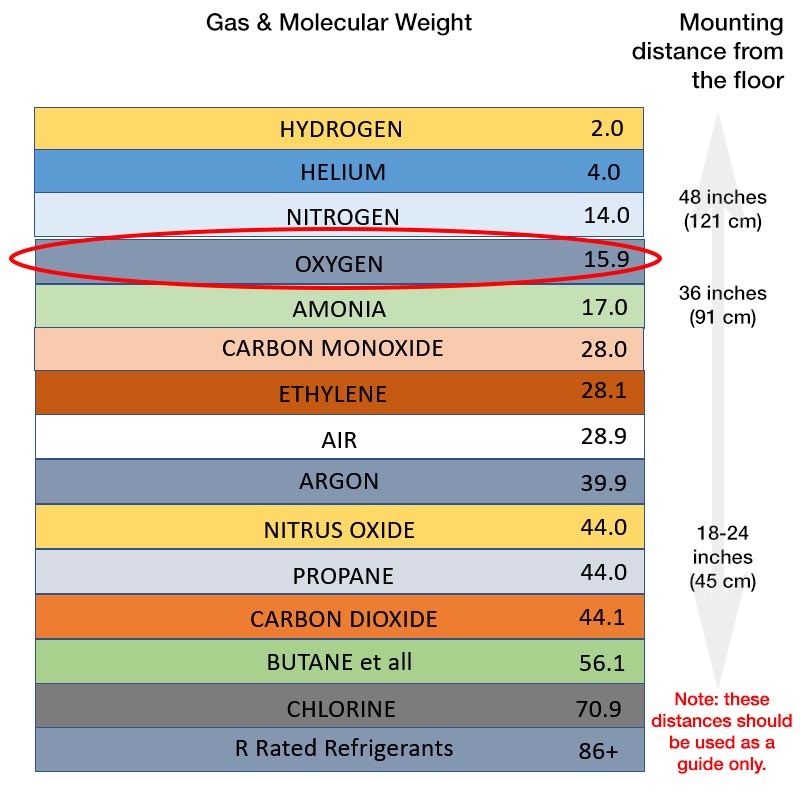

All gases have their own molecular weight. Depending on the gas weight, as it displaces air with oxygen, over time it will tend to collect or pool higher or lower in a room.

The molar mass of dry air mixed with oxygen, nitrogen and the other components is 28.9647 g/mole. In areas that are unoccupied, when testing for low oxygen levels near gases that are heavier, the oxygen sensor should be mounted lower on the wall in a room. When testing for low oxygen levels near gases that are lighter, the oxygen sensor should be mounted higher.

Here is a list of where to mount the oxygen sensor on a wall for the most common gases:

- Mount 18 inches from the floor when testing oxygen levels where refrigerants, chlorine, butane, propane, nitrous oxide or argon could collect.

- Mount 60+ inches from the floor when monitoring low oxygen levels around nitrogen, hydrogen or helium.

This chart lists the most common stored gases by molecular weight, with the lightest gases on top and the heaviest gases on the bottom.

Note that in rooms that are continuously occupied, it makes sense to put the oxygen depletion sensor close to the pipe or fittings where a gas leak is most likely to occur.

What industries use inert gas?

While there are risks in the industry pertaining to oxygen depletion, the use of inert gases are widespread across applications such as:

-

Cold Storage and Freezers: Cold storage facilities like food storage warehouses and walk-in freezers can become oxygen-deficient if there is a refrigerant or CO2 leak. Oxygen deficiency alarms are essential to protect workers who may need to enter these environments.

-

Confined Space Entry: Workers who need to enter confined spaces such as tanks, vessels, sewers, tunnels, and underground areas can be exposed to reduced oxygen levels. Oxygen deficiency alarms are crucial in these environments to ensure the safety of workers.

- Medical: Medical industries use inert and specialty gases in cryopreservation, tissue preservation and cancer treatments. Additionally, oxygen is used in emergency medical situations, such as cardiac arrests, trauma, and severe respiratory distress.

-

Laboratories: Laboratories that work with gases that could potentially displace oxygen or create hazardous atmospheres use oxygen deficiency alarms to protect lab personnel from oxygen-depleted environments.

-

Welding and Cutting: In environments where welding or cutting are done the use of inert gases like argon and helium can displace breathable oxygen. Oxygen deficiency alarms are important to warn welders and workers about potential oxygen depletion.

-

Water Treatment Plants: Facilities that handle sewage and wastewater may have areas where oxygen is displaced due to various processes. Oxygen deficiency alarms help ensure the safety of workers in such environments.

-

Aviation and Aerospace: Aircraft maintenance personnel who work in confined spaces within aircraft, spacecraft, or maintenance facilities could encounter oxygen-depleted environments. Oxygen deficiency alarms are employed to mitigate these risks.

These industries further show the importance and need of oxygen depletion safety alarms and their continued use in order to protect individuals and maintain a safe workplace.

Selecting an Oxygen Deficiency Monitor

When looking for an oxygen deficiency monitor, there are some features to consider:

- Does it meet OSHA and NIH specifications? Oxygen detectors should alarm below19.5%, and 17.5% to comply with Occupational Safety and Health Administration and National Institute of Health guidelines.

- Is it hard-wired? While wireless oxygen detectors are easy to install, the sensor should be hard-wired to the remote display to guarantee that a WiFi or network failure does not disable the alarm.

- Is it easy to install? Using an electrician to install the monitor will add significantly to the price.

- Does it come with support? Oxygen detection is easy, but knowing when or how to use it can be challenging. Can you speak with an engineer for experienced before and after sale support?

- Is it dependable? In most cases an oxygen deficiency monitor is an install once and forget it device. If the sensor fails it should inform you on the display.

- Can it communicate with a building maintenance or security system? Does the device have outputs that can provide a signal or data to your building management or security system?

- Can it control the HVAC system? If you want the alarm to open a vent or turn on a fan to clear the air, does it have relays or industry standard outputs you can use?

- Is it upgradeable? In noisy factory environments can strobes be added? Can you attach additional remote displays at doorways to warn occupants of oxygen deficient air before they enter a room?

Oxygen Deficiency Alarm with Remote Sensor

To warn occupants of oxygen depletion in an enclosed area or room, oxygen deficiency monitors are used. These include two components:

- An oxygen sensor housed in a case with audible and visual alarms to warn occupants INSIDE the confined space

- One or more remote displays with duplicate audible and visual alarms to warn personnel OUTSIDE the space and before entering the room

The two components are linked by a cable that sends the oxygen level data and power from the monitor to the remote display in real time. Typically a wireless connection is avoided as problems with networks and interference from building materials like concrete and steel render the system useless.

In addition to the sensor and remote display(s), a data link can be made utilizing the devices 4-20 mA output between the sensor and a control panel or dashboard to warn offsite personnel if an oxygen depletion alarm has occurred.

Oxygen Depletion Safety Alarm

Our Oxygen Depletion Deficiency Safety Alarm is designed to protect customers and workers near stored inert gases like nitrogen, argon, helium, nitrous oxide, welding gases and more.

This oxygen monitor has both audible and visual alarms. 3 built-in relays are triggered when oxygen levels fall below 19.5%, 17.5%, and 15% respectively and can control an exhaust fan or send an alarm to the fire department or monitoring company. The alarm levels are user configurable to allow for specific applications.

Additionally, the Oxygen Depletion Safety Alarm can operate in facilities down to -50C (-58F) to protect employees in cold storage areas.

Conclusion

The need for monitoring oxygen levels in a room can be critical for those working and handling the gas type, and CO2Meter strives in being able to provide fixed and personal devices, that continue to save lives today.

For more information on Oxygen Depletion Monitoring and selecting the proper monitoring device, contact us today.

References:

https://en.wikipedia.org/wiki/Atmosphere_of_Earth

https://www.ccohs.ca/oshanswers/safety_haz/welding/fumes.html

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.146

https://www.engineeringtoolbox.com/molecular-mass-air-d_679.html