Biological Incubators

Enhance Growth in Cell Culture Incubators

CO2 incubators used in life sciences, medical research, and pharmaceutical industries provide environmental conditions to enhance cell growth. The are also used to provide sterile conditions for cultivation in fields where cells must grow in a completely germ-free environment.

A meter or sensor that can provide consistent CO2 levels throughout the incubation process is vital in order to maintain proper control of pH levels and manage ideal cell or tissue growth.

Learn more about our CO2 meters, sensors, and monitors below.

-

CO2 Sensor

Incubator IR CO2 Sensor Analyzer

The Incubator IR CO2 Sensor is designed specifically to monitor and detect carbon dioxide levels in cell incubators to manage ideal cell...

$1,999.00 USD$1,999.00 USD$1,999.00 USD -

Select optionssensors

Zirconia Oxygen Sensor System

The Zirconia Oxygen Sensor System offers a complete oxygen level measurement solution removing the need for customers to develop their...

5.0 / 5.0

(1) ( 1 )

$549.00 USD $1,299.00 USD$549.00 USD$549.00 USD $1,299.00 USD -

Select options

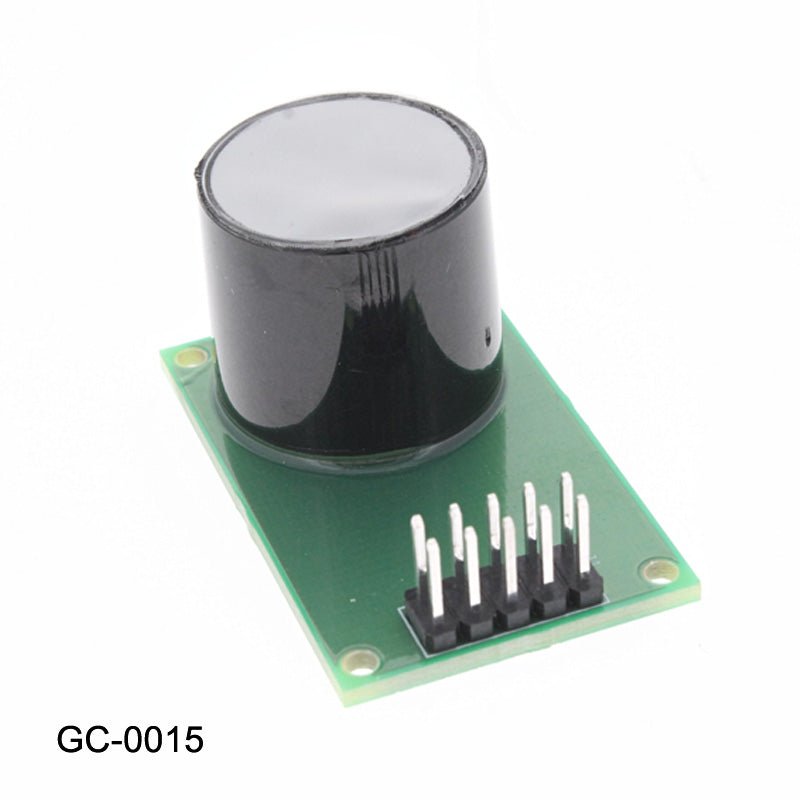

The (033-9-0023) K33 ICB CO2 sensor (formerly known as SE-0025) measures up to 10% carbon dioxide in biological or scientific applications where high...

5.0 / 5.0

(3) ( 3 )

$175.00 USD$175.00 USD$175.00 USD -

Handheld

0-25% Oxygen O2 Sampling Data Logger

The 25% Oxygen Sampling Data Logger is designed to measure oxygen levels over time in enclosed environments, used primarily in life...

$1,999.00 USD$1,999.00 USD$1,999.00 USD -

The 20% Carbon Dioxide Sampling Data Logger is designed to measure carbon dioxide levels over time in enclosed environments, used primarily...

$1,999.00 USD$1,999.00 USD$1,999.00 USD -

The 25% Oxygen and 100% Carbon Dioxide Sampling Data Logger is is designed to simultaneously measure multiple gas concentrations through...

$2,250.00 USD$2,250.00 USD$2,250.00 USD -

The 25% Oxygen and 20% Carbon Dioxide Sampling Data Logger is is designed to simultaneously measure multiple gas concentrations through...

$2,250.00 USD$2,250.00 USD$2,250.00 USD -

The 25% Oxygen, 5000ppm CO and 1% Carbon Dioxide Sampling Data Logger is is designed to simultaneously measure multiple gas...

$2,499.00 USD$2,499.00 USD$2,499.00 USD -

Select optionsHandheld

Multi Gas Sampling Data Logger

The Multi Gas Sampling Data Logger is is designed to simultaneously measure multiple gas concentrations through a sampling method. Utilizing a...

5.0 / 5.0

(1) ( 1 )

$1,999.00 USD$2,250.00 USD$2,250.00 USD -

Select optionssensors

SprintIR®-6S-5 5% CO2 Sensor

The SprintIR®-6S-5 5% CO2 Sensor (formerly known as GC-0028) can take up to 20 readings per second, making it ideal for...

5.0 / 5.0

(1) ( 1 )

$318.00 USD $399.00 USD$318.00 USD$318.00 USD $399.00 USD -

Select optionssensors

ExplorIR®-W 5% CO2 Sensor

The ExplorIR®-W (formerly known as CozIR Wide Range) is a low power, high performance CO2 sensor that measures 5% CO2 in battery...

4.8 / 5.0

(5) ( 5 )

$129.00 USD$197.00 USD$197.00 USD -

The 1% Carbon Dioxide Sampling Data Logger is designed to measure carbon dioxide concentrations in enclosed environments such as indoor...

$1,999.00 USD$1,999.00 USD$1,999.00 USD

Don't Take Our Word for it, Take Theirs

Matthew Weintraub

Plant Manager

"Your solutions meet the code requirements and because of you our facility is much safer."

Angela Ihrig

Supply Chain Manager

"CO2Meter has helped protect 150+ of our customers sites and ensure they are compliant and safe."

Michael Hudkins, CFPS

Fire Plans Examiner/Fire Inspector II

"I would recommend CO2Meter gas training to anyone, it inspired us to be keenly aware of what to inspect."

Keith Isoldi

Chief Operating Officer

"I have always worked with CO2Meter because they are the industry leader."

Kelly Kissock

Faculty Director

"Easy to install, Our CO2 tank gassed off and the meter near it worked perfectly!"

Stay Informed with Our Latest Updates

Subscribe to our newsletter for the latest news, product updates, and industry insights.

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO

CO2Meter is working with our global supply chain to minimize disruptions

Due to imposed tariffs, Quotes will be honored for 24 hours and may require a revised PO