Most CO2 sensors today work by measuring light absorbed by CO2 molecules in a gas sample. The more CO2 molecules present, the more light is absorbed, allowing the sensor to calculate an accurate CO2 concentration.

What is the principle of non-dispersive infrared?

NDIR, or non-dispersive infrared is an industry term and the most common technology for CO2 sensing. NDIR sensors work by using an infrared (IR) lamp to direct waves of light through a tube filled with a sample of air. This air moves toward an optical filter in front of an IR light detector. The IR light detector measures the amount of IR light that passes through the optical filter.

In an NDIR CO2 sensor, the band of IR radiation produced by the lamp is close to the 4.26-micron absorption band of CO2. Because the IR spectrum of CO2 is unique, matching the light source wavelength serves as a signature or "fingerprint" to identify the CO2 molecule.

As the IR light passes through the sample tube of air, the CO2 gas molecules absorb the specific band of IR light while letting other wavelengths of light pass through. At the detector end, the remaining light hits an optical filter that absorbs every wavelength of light except the 4.26 micon wavelength absorbed by CO2 molecules in the sample tube.

Finally, an IR detector reads the remaining amount of light that was not absorbed by the CO2 molecules or the optical filter. The decrease in transmitted infrared light is proportional to the CO2 gas concentration.

Components of NDIR CO2 Sensors: What Makes Them Accurate:

NDIR CO2 Sensors typically consist of:

-

IR Light Source: The NDIR sensor uses a light source that emits infrared radiation at specific wavelengths. Common light sources include infrared LEDs or IR lamps. These light sources provides the energy needed for the subsequent interactions with the CO2 molecules in the gas sample.

-

Gas Sample Cell: The gas sample cell is a chamber through which the gas to be analyzed (the sample gas) passes. It allows the infrared light to interact with the CO2 molecules in the gas. The sample cell is typically made of materials that allow the infrared light to pass through without significant absorption and is polished to reflect the maximum amount of IR light.

-

Optical Filters: Optical filters are used to select specific wavelengths of infrared light that are known to be absorbed by CO2 molecules. By using the appropriate filters, the sensor can ensure that only the 4.26 micon wavelengths are detected by the detector, enhancing overall measurement accuracy.

-

Detector: The detector is a crucial component of the NDIR sensor. It measures the amount of infrared light that passes through the gas sample after interacting with CO2 molecules. The detector's signal provides information about the concentration of CO2 in the sample.

-

Reference Channel: Many NDIR CO2 sensors include a reference channel. This channel measures the amount of infrared light that passes through the sample without being absorbed by CO2. The reference channel serves as a baseline, allowing the sensor to compensate for variations in the light source's intensity and environmental conditions, leading to much more accurate measurements.

-

Signal Processing and Electronics: The detector's output signal and the reference channel signal are processed by ICs around the sensor. These electronics include an analog to digital converter, factory calibration and offset tables stored in memory, and compensation algorithms that take input from external temperature, humidity, and pressure sensors that can influence the final measurement.

This precise system design makes NDIR sensors the standard for many applications like indoor air quality, industrial safety, and greenhouse monitoring; providing stable measurements over the sensor's lifetime.

How is the CO2 levels are calculated using NDIR sensors

The difference between the amount of light radiated by the IR lamp and the amount of IR light received by the detector is measured. Since the difference is the result of the light being absorbed by the CO2 molecules in the air inside the tube, it is directly proportional to the number of CO2 molecules in the air sample tube.

All measurements start out as analog micro-voltages. While some sensors output this as an analog voltage or 4-20mA signal, some also include an analog to digital converter on the sensor PCB that converts the voltages into serial or RS-485 output. Serial output is especially useful for using NDIR CO2 sensors with Arduino or Raspberry Pi microcontrollers.

Early Carbon Dioxide Sensor Technologies

Since Joseph Black, a Scottish chemist and physician first identified carbon dioxide in the 1750s, scientists have looked for a way to measure this common gas. One of the earliest CO2 measurement devices was a mercury manometer. Manometers use a U-shaped glass tube filled with mercury to measure gas pressure. If temperature, pressure, and volume of a dry gas sample containing CO2 molecules are known, the moles of CO2 can be calculated using the Ideal gas law (PV=nRT).

While mercury manometers can be very accurate, the procedure for measuring CO2 levels in air samples can take hours. That’s why when Charles Keeling was asked by the US Weather Bureau to begin taking hourly atmospheric CO2 measurements at the Mauna Loa volcano in Hawaii he used an early infrared (IR) gas analyzer calibrated against his manometer. The original Applied Physics Corp. Infrared Gas Analyzer operated on Mauna Loa from 1958 until 2006.

Like every IR gas sensor, the analyzer at Mauna Loa used the same basic principle for measuring CO2. It has an infrared light radiation source at one end of a gas sample tube and an IR detector at the other. The band of infrared radiation is very close to the absorption band of CO2. As a result, the amount of light radiation that is absorbed by the CO2 molecules is proportional to the amount of carbon dioxide in the gas sample. However, since low levels of CO2 do not absorb much light, a long tube is needed before the effect can be measured.

While the original IR gas analyzer was accurate, it was bulky. The sample tube alone was 40cm (16 inches) long.

The challenge is getting the right balance. Engineers use a longer optical path to measure lower levels of CO2 more accurately - which means a larger gas sample chamber. On the other hand, in ambient air environments - such as schools, offices, and homes - the demand is for ever-smaller sensors to fit neatly inside compact devices.

Small NDIR CO2 Sensor Breakthrough

An engineering breakthrough occurred in 1993 when SenseAir AB patented a design for small-footprint CO2 sensors. These sensors solved the size problem by using folded optics and metalized molded plastic to reflect the light through a curved shape (referred to as a 'waveguide') that was longer than the footprint of the sensor module. The highly reflective coating ensured that the CO2 molecules inside the gas sample chamber would absorb the same amount of light as traditional straight-path design.

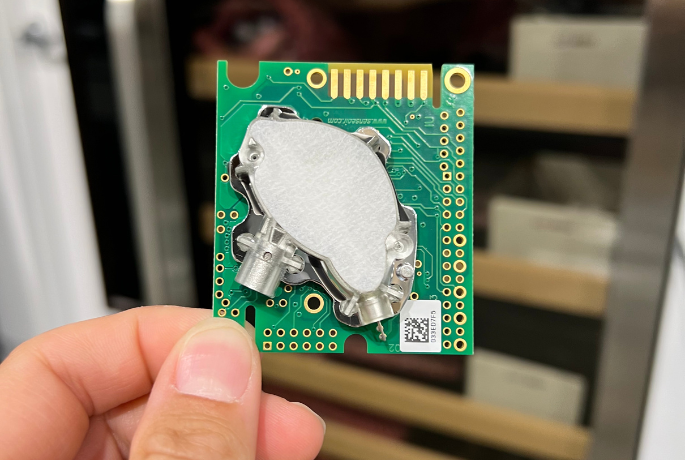

By using advanced optics, new waveguide designs allowed for progressively smaller sensors with increased sensitivity. For example, in 2003 SenseAir's K20 CO2 sensor (shown above) used a "banana" waveguide design. This sensor was used for many years in OEM consumer safety products.

Modern NDIR CO2 Sensors

Today's newest generation of CO2 sensors have even more optimized waveguides, allowing a longer optical light path to be folded into an even smaller 8 mm x 33mm x 20mm footprint.

In addition to a smaller size, new mid-range infrared light-emitting diode (LED) light sources have been developed that allow NDIR sensors to operate at much lower power levels. Combined with a photo-diode light detector, these solid-state sensors also provide a much longer life-span.

For example, many modern day sensors now consume only 3mW of power, while typical incandescent IR sensors consume 50 to 200mW. This low power consumption makes the new generation of NDIR CO2 sensors capable of running for months on battery or solar power alone.

The K30 NDIR CO2 Sensor

One of the most popular NDIR CO2 sensors is the K30 CO2 Sensor, used in HVAC, indoor air quality and scientific applications. This sensor features a compact design with high accuracy, stability and low power consumption ideal for those looking to gain continuous monitoring.

The K30 also uses folded optics to maintain a long optical path with a compact sensor footprint. This design overall ensures precise CO2 measurement while seamlessly integrating into many OEM products and projects. With options for both analog, PWM, and UART serial outputs the K30 can easily integrate with Arduino, Raspberry Pi, and other microcontroller-based systems making it a true favorite across many CO2 monitoring projects.

To learn more about what CO2 sensor is right for your project, click here.

The Evolution and Future of NDIR CO2 Sensors

Historically, CO2 measurement as we've seen was bulky and time consuming, relying on mercury manometers and early infrared analyzers with long gas sample tubes. With innovations like the K30 it allows modern sensors to maintain measurement accuracy and be compact enough to fit small footprints.

When we look toward the future we see advancements in photoacoustic spectroscopy (PAS) and MEMS which may yield even smaller, more power-efficiency sensing with further expansion possibilities for smart homes, IoT and environmental monitoring.

For more information on CO2 sensing technologies or to speak to a CO2Meter expert, contact us today.