Long-term storage of grains like wheat, oats and corn (technically a grain after drying) have been a problem since the dawn of agriculture. Early farmers stored grain in urns, bags and baskets. Unfortunately, these crude storage methods resulted in grain losses approaching half the initial crop.

Even today, this problem continues in less developed countries. In some places, grain storage losses are still the same as it was 1,000 years ago. There is evidence global starvation could be alleviated simply by improved grain storage and transportation practices alone.

The need for long-term storage solutions is made more critical in the United States by the fact that some grains are held up to 12 months in farm silos before processing. This means the stored grains are at high risk for damage during the hot, moist summer months.

Today farmers use a variety of techniques to limit grain losses. The two most common are insecticides and controlled atmosphere storage (CA). Of the two, CA storage is safer, better for the environment and has several benefits not found in older grain storage loss solutions.

Solutions to Grain Loss during Storage

Grain loss or damage during storage are the result of 2 major factors: insects who eat the grain, and rot or mold caused by high storage temperature and humidity. Modern grain storage operations use a variety of techniques to limit grain losses including insecticides, protectants and fumigants to control insects, and Controlled Atmosphere Storage to combat rot and mold.

Insect Control

Insecticides: Before a grain silo is filled, the walls and floor are sprayed with a topical insecticide. The advantage of this type of chemical treatment is that it provides long-term protection. The disadvantage is that while it creates a barrier for new insects, it will not kill an established infestation already in the grain.

Protectants: in already filled silos or non-silo storage, grain is sprayed with an insecticide that forms a protective barrier against insects. Because a protectant is also an insecticide, it has the same long-term protection advantage. And like insecticides, it will not kill an established insect infestation already in the grain.

Fumigants: Fumigants are gases that kill insects living in the grain. Fumigation is done when the grain silo is full to combat an infestation that has already taken place. While fumigation can be effective in stopping an existing infestation, it has no long-term effect.

The disadvantages of fumigants is that the chemicals used are highly toxic. Full SCBA gear must be used during fumigation. Fumigants are also subject to failure if too little chemical is used, if the grain is too hot or too cold, or if the humidity is too high.

For example, one of the most common chemicals used to combat pests and rodents in grain storage is Aluminum or Magnesium Phosphide. When subject to moisture, these chemicals release a deadly gas. The advantage of this treatment is that it is relatively inexpensive. The disadvantage is that pesticides are a common cause of poisoning of agricultural workers. In addition, studies have shown insects can develop resistance to pesticides. As a result, chemical companies now produce a vast array of insecticides targeted to specific insects and grains that must be rotated yearly to combat insect mutations.

Controlled Atmosphere Storage

While insects can hurt stored grains, rot and mold can have a much greater impact. Freezing winter temperatures will minimize the growth of bacteria that causes rot or the fungi that cause mold. However, once the grain is above freezing, rot and mold will start again.

The most basic controlled atmosphere (CA) storage techniques start with grain dried below 12% moisture content before storing it in a sealed structure or silo. Drying can be accomplished by aeriation fans as it is moved into a CA enclosure. During storage, aeration and fans are used to regulate temperature and humidity.

However, regulating temperature and humidity isn’t enough. In modern farms, variations in nitrogen, oxygen and carbon dioxide levels in the CA storage buildings are monitored to alert farmers to the presence of destructive insects or mold.

For example, carbon dioxide levels can be used as a marker for metabolic processes. Because CO2 is a natural trace gas that comprises only about 0.039% (390ppm) of ambient air, spikes in CO2 levels in a CA structure are signs of infestation.

CA for Pest Control

In addition to monitoring and controlling mold, carbon dioxide can be used as a fumigant in lieu of pesticides. According to a report prepared by the Food and Agriculture Organization of the United Nations,

“Insects are generally killed more rapidly by carbon dioxide than they are by lack of oxygen. A concentration of 6 percent carbon dioxide will give over 95 percent control of most stored grain insects after a 4 day exposure at 27°C or higher (Jay, 1971); however, longer periods are needed for complete kill. Banks (1979) suggested that an initial level exceeding 70 percent carbon dioxide and maintained above 35 percent for ten days is appropriate for complete insect control.”

Controlled atmosphere storage is safer, more environmental and points to the future of modern grain storage practices.

Food Storage Gas Monitoring

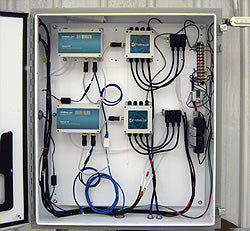

CO2Meter.com has been fortunate to work on several CA storage projects. Three of our most popular products in this industry are:

100% CO2 + 25% O2 Monitor Logger – Measure, log and control both carbon dioxide and oxygen levels drawn from a gas source. Our CO2 + oxygen monitor is useful for modified atmosphere packaging (MAP), controlled atmosphere storage (CA) applications, incubation, fermentation or for bench-top gas analysis. It features a built-in sampling pump, real-time LCD readout, and built-in data logging. Learn more...

100% CO2 + 25% O2 Monitor Logger – Measure, log and control both carbon dioxide and oxygen levels drawn from a gas source. Our CO2 + oxygen monitor is useful for modified atmosphere packaging (MAP), controlled atmosphere storage (CA) applications, incubation, fermentation or for bench-top gas analysis. It features a built-in sampling pump, real-time LCD readout, and built-in data logging. Learn more...

Portable CO2 Sampling Data Logger – This hand-held unit features an internal pump to let you reach deep inside bulk storage bins or silos to take air quality samples. With the built-in internal memory, samples can be taken over time and downloaded to a PC to determine the rate of change of CO2 levels - up means mold or fungus, down means leaks in grain storage containers sealed with CO2 inside. Learn more...