News

Sidebar

Categories

Temperature Change Impacts Oxygen Sensors

If you work with gases like we do at CO2Meter, you already know that the ideal gas law PV=nRT shows that absolute gas concentration decreases as temperature increases. This relationship is important to anyone measuring oxygen levels during combustion, fermentation, distillation or algae production.

But like they say, “a picture is worth a thousand words.”

That’s what we discovered when we measured the change in oxygen gas levels in a sealed environment using our UVFlux 25% Oxygen sensor and Gaslab software. Using the built-in RS232 protocol, the UVFlux sensor samples both the oxygen level and the temperature inside the sensor once per second.

Over several minutes we raised the temperature of the sample from 24C to 34C, and were able to see in real-time the oxygen concentration in the sample drop from 20.6% to 19.8%.

click image on right for larger view.

Note the internal sensors components are corrected for operating temperature over the range. No compensation is made for the temperature of the gas being measured. Also note the change in oxygen level measured slightly lagged behind the change in temperature.

In addition to temperature, the % relative humidity will have an impact on the oxygen concentration in a sample. At the same pressure and temperature, a volume of oxygen at 100% humidity will contain less oxygen molecules than if there were no water.

Constant CO2 Level in Greenhouse

Controlled CO2 gas inflow and improved air mixture can help maintain optimum CO2 levels in small indoor greenhouses or grow rooms. These were the lessons learned after working with a client who was attempting to control the CO2 levels in a group of 3 10x20” greenhouses.

The client wanted to maintain different consistent CO2 levels in each greenhouse to test the effects on the plants inside. To control the CO2, he used our iSense 1% CO2 Level Controller, a more industrial version of our Day Night CO2 Monitor & Controller for Greenhouses.

In one test greenhouse, the CO2 controller was set to turn on a CO2 Tank Regulator with Solenoid Valve at 700ppm and turn it off at 1,400ppm. While the controller correctly turned the regulator on at 700ppm, the CO2 levels were overshooting 1,400ppm before switching off the solenoid on the regulator. As a result, the clients was seeing wild swings of CO2 levels instead of the consistent level required for his experimentation.

After looking at his CO2 levels vs. time graphs, we noticed a pattern of a quick rise in the level of CO2, followed by slow drops. This lead to the conclusion that the greenhouse was being quickly flooded with CO2 before the CO2 sensor in the controller had a chance to react to the change in CO2 levels.

In other words, the problem was being caused by inefficient air mixture in an enclosed area.

In a perfect world the CO2 flow rate could be set to exactly match the CO2 loss. However, in the real world, minimum and maximum level switches are required to turn the regulator on and off to keep the CO2 levels within a specified range.

We suggested three changes to the client’s setup to help solve his problem.

- Increase air circulation with fans, especially ones placed near the CO2 gas inlet into the greenhouse.

- Make a CO2 delivery tube like industrial greenhouses with propane CO2 systems use. Drill small holes in a long piece of flexible tubing that runs the length of the greenhouse, then hang the tubing above the plants. Since carbon dioxide is heavier than normal air, it will naturally mix as it falls.

- This decreases the amount of CO2 released between the time the room reaches the optimum CO2 level and the controller senses it. In addition, a good regulator with flow control not only limits the amount of CO2 that is released, but it maintains a consistent level of flow as the CO2 is used and the tank pressure changes.

Using our suggestions, the client will be able to maintain a more consistent CO2 level in the test greenhouses in order to complete their experiments.

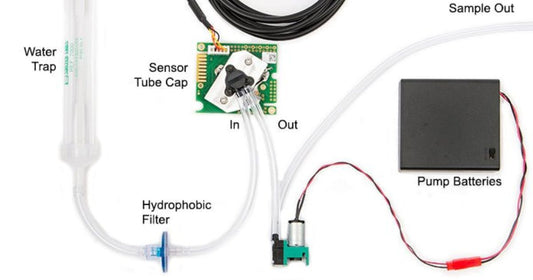

Gas Sensor Response Time Increases with Length of Tubing

CO2 sampling sensors in a react at different rates depending on the length of the tubing used between the source gas and the sensor.In a closed loop system.

Senseair CO2 Sensor Pressure Dependence

All infrared (NDIR) CO2 sensors have a dependence on pressure. This is because of the physics principle used to measure CO2 concentration.

The NDIR type of sensor measures the IR radiation absorbed by CO2 molecules, which corresponds to the mole concentration. When pressure increases, the number of molecules in a given volume also increases linearly. Conversely, when pressure decreases (higher altitudes, for example) the number of molecules decrease.

This app note includes both general information about Senseair sensors and pressure, as well as the equation for computing true CO2 level readings at various pressures useful for any NDIR CO2 sensor.

Click here to read or download the app note (pdf).

Note that like CO2 sensors, oxygen sensors are also pressure and altitude dependent. We had a client in Bangalore, India purchase a CM-0505 O2 Data Logger. He reported that it was reading 18.3% instead of the expected 20.9% when exposed to outdoor ambient air.

I looked up the Bangalore, India Airport information and found that the altitude was 2,890 feet above sea level. Using this chart we found online, we were able to confirm for the client that in fact, his meter was performing within the expected tolerances.

Can CO2 influence plant transpiration and biodiversity?

Guest post by Michael Forster, Edaphic Scientific Pty Ltd

Everyone knows that plants need carbon dioxide to grow. But fewer people know that carbon dioxide can also effect plant transpiration and even the water balance of entire ecosystems and catchments. Even fewer people know that carbon dioxide can affect biodiversity and which plant species are more common than other species.

Let’s just leave aside all of the topics on how increasing carbon dioxide is leading to global warming and how this, in turn, is impacting on plant species. Let’s just focus purely on how increasing atmospheric carbon dioxide changes the fundamental physiology of plants and how this, in turn, can lead to changes in transpiration and which species are more common in a forest.

Firstly, how do we know all of this? Scientists have been conducting experiments for years now where they have artificially increased atmospheric carbon dioxide around plants and forests.

They do this via experiments called FACE – or Free Air Carbon Enrichment – where massive towers gorge out copious amounts of CO2. Image: FACE experiment at Duke University, North Carolina, USA (source: https://www.czen.org/content/duke-forest-face-experiment)

What these experiments have generally shown is that plants actually like it when there is more carbon dioxide in the atmosphere. Plants generally grow larger and faster with more CO2. The process is similar to when you add fertilizer to the soil to assist the plant’s growth. Instead, we are adding fertilizer to the atmosphere in the form of more carbon dioxide. As there is more carbon dioxide in the atmosphere, it is generally easier for plants to perform photosynthesis and accumulate biomass.

In terms of transpiration, or plant water use, an increase in atmospheric CO2 means that stomata, or the pores on leaves that exchange gases between the leaf and the atmosphere, do not need to open as much. This means that, at the scale of a leaf, less water is lost and there is lower transpiration. With increased photosynthesis and lower water loss, then the water efficiency of plants is increased.

So it seems that more carbon dioxide in the atmosphere is a good thing for plants – they grow faster and use less water. However, nothing in biology is so simple. Yes the water loss at the scale of a leaf is lower, however, there are more leaves on the plant because it is growing faster and bigger. So, at the scale of the entire plant, water use or transpiration is actually higher.

This may seem trivial but consider this: a 30 metre (100 foot) tall tree transpires about 200 litres (53 gallons) on a good day. A forest of woodland contains many thousands to millions of individual trees all transpiring about 200 litres per day. This can impact on water reserves – particularly around dams for drinking water or irrigation. With increased atmospheric carbon dioxide, all of those trees may potentially transpire more water and having a greater impact on water supplies.

Also, not all species of plants are created equally. Increasing carbon dioxide does improve growth but some species perform better than others. In a woodland or rainforest, some species may grow better and out compete their neighboring plants. That is, some species may become more common and others scarce. This may then impact on the animals that rely on those plants for food and shelter.

Increasing atmospheric carbon dioxide can benefit plants – something greenhouse and glasshouse growers use to their advantage. However, the process and outcomes are complex. In the real world increasing carbon dioxide does not benefit all plants.

Stay Informed with Our Latest Updates

Subscribe to our newsletter for the latest news, product updates, and industry insights.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.

Still need Help? Talk to an Expert.

We'll be happy to help you find the right product!

Call us at 877.678.4259.