Cryogenic safety is ensuring proper procedures are followed when working with cryogenic gases and liquids.

Contents

- Cryogenic Gas & Liquid Uses

- Cryogenic Gas Pressure, Density and Boiling Points Chart

- Cryogenic Gas & Liquid Safety

- Cryogenic Gas & Liquid Safety Tools

- Cryogenic Gas & Liquid Safety Whitepaper

Cryogenic gases (called cryogens) include argon, helium, hydrogen, nitrogen, oxygen, methane and CO2. These gases are used to produce very low temperatures in the laboratory, in research facilities, in medicine and in industry.

Cryogens are created by pressurizing gases above their triple point where they change state from a gas to a liquid. In their liquid state they are very cold. The development of the process of creating and storing low temperature gases has opened up the field of cryogenics from the research lab to a host of industrial and health-related processes around us.

Learn more about cryogenics here.

While cryogenics has created great benefits, cryogens, if not handled correctly, can be unsafe. It's important to know what cryogenic gases are, how they are used and how they can be used safely.

Cryogenic Gas & Liquid Uses

Cryogenic gases and liquids are used far more often than you might imagine. For example, the cryogenic liquid; nitrogen, is used as an industrial cryogenic gas to freeze plastic before it is ground up and recycled. Applications such as these continue to use cryogenic gases in many different areas such as cryogenics, food preservation, cryosurgery, and cryotherapy services.

All applications that use cryogenic liquids or gases require safety monitoring as detailed by OSHA. Monitoring nitrogen or carbon dioxide requires oxygen depletion monitoring. Oxygen is normally 20.9% in ambient air. As it is displaced by other gases in an enclosed area, the oxygen level can drop to 18% - the OSHA minimum oxygen level for workplace safety.

Here are some of the many applications where cryogenic gases are used:

Food processing, an industry that mainly uses liquid nitrogen driven with high density (BTU) available by weight. CO2 is used as well where higher volumes of gas are required because of the process dynamics. Either gas is interchangeable with modified process times, in flush tunnel and immersion processes.

In the case of CO2 storage, normally 0.04% in the atmosphere, gas or liquid CO2 storage requires additional monitoring. While any gas can displace oxygen, the CO2 displacement of oxygen adds a potential for oxygen depletion and is monitored to the personal exposure limit of 1.5% CO2 concentration.

Some health applications, chemical properties, temperature or economics favor the cryogen liquid helium. For example, liquid helium is essential for operating MRI machines and many superconducting applications, such as infrared imaging.

Argon is also used to cool infrared-sensitive detectors to “see” in the long wavelengths. For example, argon is used to cool the underground FermiLab particle detector used to scan for neutrinos

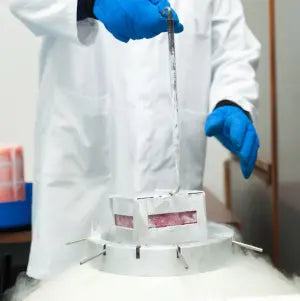

Liquid nitrogen or carbon dioxide are used to freeze tissue samples in labs or research facilities, or to store embryos for invitro fertilization. Surgeons and dermatologists also used liquid nitrogen as an aerosol to freeze and cauterize basil cells and tumors.

Cryosurgery is used to freeze or destroy tissues like cancer in the body during surgery or on the skin to kill cancer cells. While cryosurgery is a type of cryotherapy, most people today think of athletes who use cold therapy as a way to deaden nerves and potentially speed healing. While some types of cryotherapy are controversial, they have lead to the creation of cryospas where the general public can get cryotherapy treatments.

Another application where cryogenic fluids are used is dry cleaning, which uses liquid CO2 as a solvent to remove soil from fabric without the need for flammable solvents like methylene chloride.

If you drink decaffeinated coffee, the caffeine is removed by CO2 which is selective to dissolving caffeine while leaving the terpenes that influence the flavor. Previous methods using methyl solvents removed desired tastes or added undesired flavors and aroma.

A similar process is used to extract oils from cannabis and hemp using CO2 where butane or ethane are used to achieve the desired result. In the case of cannabis hydrocarbon extraction, this process requires complete evacuation of oxygen in the process chamber, and is done by a nitrogen flush. Even a small amount of oxygen can affect the oil extracted in many undesirable ways including taste, selectivity, and potency. All of the extracted product is the result of solvent distillation, when the pressure is reduced and the solvent returns to a gaseous state and the oil or resin remains in liquid state to further reduce to the desired product.

In addition, precision welding on an industrial scale uses liquid argon, CO2 or nitrogen to displace all the oxygen at the point of the weld for specific metals. This oxygen purging creates maximum penetration with the minimum distortion. This is where the ability to measure oxygen concentration at the parts-per-million level can improve the quality and consistency of the weld while reducing the explosive potential.

In every application above, cryogenic safety is important when handling or working around tanks of liquid cryogenic gases.

Cryogenic Gas Pressure, Density and Boiling Points Chart

This chart lists all the common cryogenic gases as well as the temperature at which they change from liquids to gas (boiling point). The lower the boiling point, the more colder the gas can become. Note that at these low temperatures, skin can freeze instantaneously.

Also note that the liquids to gas expansion ratio shows how much air is displaced by a given amount of gas. For example, one liter of liquid argon expands to 860 liters of gas. This means that even a small leak of cryogenic gases can quickly displace all the breathable air in an enclosed area.

|

Cryogen |

Boiling point (1 atm) oC(oF) |

Critical pressure psiga |

Liquid density, g/L |

Gas density (27oC), g/L |

Liquid-to-gas expansion ratio |

Type of gas |

|

Argon |

-186(-303) |

710 |

1402 |

1.63 |

860 |

Inert |

|

Helium |

-269(-452) |

34 |

125 |

0.16 |

780 |

Inert |

|

Hydrogen |

-253(-423) |

188 |

71 |

0.082 |

865 |

Flammable |

|

Nitrogen |

-196(-321) |

492 |

808 |

2.25 |

710 |

Inert |

|

Oxygen |

-183(-297) |

736 |

1410 |

1.4 |

875 |

Flammable |

|

Methane |

-161(-256) |

673 |

425 |

0.72 |

650 |

Flammable |

|

CO2 |

-79(-108) |

1071 |

100 |

20 |

535 |

Inert |

Cryogenic Gas & Liquid Safety

The challenge with cryogens is safety. All of the cryogenic gases have potential safety problems beyond their freezing hazards. As they return to a gas they expand rapidly to many times greater than their volume. For example, nitrogen gas expands 700 times its liquid volume (see chart). As a result, the expanding gas can quickly displace other gases. The main area of concern is oxygen, where oxygen displacement can result in asphyxiation or death.

Aside from these use cases and applications regarding ensuring safety in the workplace, one should adhere to the following:

Skin tissue: Extreme cold can rapidly freeze skin tissue, which is why liquid Nitrogen is often used to freeze off unwanted tissue by dermatologists. However, this presents a danger when it meets healthy tissue: skin can crack and freeze causing frostbite. Some extremities might be protected by the Leidenfrost Effect in which liquids that comes into contact with something much hotter than itself forms an insulating layer of vapor to prevent the liquids from immediately boiling, this can only last so long, and it is for ones best interest to wear gloves and PPE - personal protective equipment.

Asphyxiation: Inert gas asphyxiation is a form of asphyxiation which results from breathing in a gas in the absence or Oxygen or low amount of Oxygen rather than air. Physiologically inert gases such as liquid Nitrogen does not act upon the heart or hemoglobin and instead reduces Oxygen concentration in blood to low

levels, depriving cells of Oxygen. Breathing in these gases with deficient Oxygen can have immediate and serious effects after a few short breaths. Gases such as liquid Nitrogen have no taste or smell, so it is impossible to know if you are inhaling the hazard.

It's important to have a gas detection monitor that can monitor the level of oxygen in the environment, so an asphyxiation incident does not occur.

Pressure build up: We know that heating materials up to extremely high temperatures can cause explosions, but so can cooling them down. Cooling a substance makes it denser and less likely to expand, however gases under pressure risk leaking and expanding inside their container. When a gas expands inside an enclosed container, the pressure inside can push outwards causing leaks or even an explosion.

Cryogenic Gas & Liquid Safety Whitepaper

The use of cryogenic gases and liquids such as nitrogen and helium require careful handling and adherence to specific guidelines and procedures.

In this whitepaper, CO2Meter delivers key insights that help educate on the hazards associated with cryogenic gases and liquids and safety best practices to keep you, your staff, and your establishment protected.

Contents

- Cryogenic Applications across the Industry

- The Importance of Gas Safety

- Hazards Associated with Cryogenic Liquids

- Cryogenic Liquids Standards and Regulations

- Importance of Measuring for Oxygen Depletion

- Industrial Gas Detection Solutions

Cryogenic Gas & Liquid Safety Tools

Protecting yourself from exposure to cryogenic gas or liquid starts with an RAD-0002-ZR-HS2 Oxygen Deficiency Depletion Safety Alarm. It is designed notify staff in enclosed areas near storage cylinders of nitrogen, argon, ammonia, chlorine, propane, nitrous oxide, helium, argon, or other inert gases if a leak occurs.

One cannot talk about cryogens without talking about proper safety training. In addition to wearing the proper PPE and having proper signage, employees around cryogens need training to determine what to do in the event of an emergency. One good place to start is the OSHA website.

Best Practices for Installing Oxygen Deficiency Alarms in Cryogenic Storage Areas

To maximize protection:

-

Place alarms at breathing height in storage rooms, labs, and cryogenic cylinder areas.

-

Install monitors in confined spaces where oxygen displacement is most likely.

-

Integrate alarms with ventilation and building management systems for automatic response.

-

Test and calibrate devices regularly to maintain accuracy.

The RAD-0002-ZR-HS2 Oxygen Deficiency Alarm offers flexibility for both new and existing cryogenic installations, making it a best-practice choice for proactive safety.

Although cryogenic gases are necessities in many applications, they are still hazardous, and the proper precautions must be taken in order to avoid catastrophes.

References

https://www.ncnr.nist.gov/equipment/cryostats/CryogenSafety.pdf

https://en.wikipedia.org/wiki/Inert_gas_asphyxiation

https://www.bbc.com/news/magazine-19870668

https://www.cganet.com/refrigerated-and-cryogenic-liquid-safety/

https://lasers.colostate.edu/wp-content/uploads/2019/04/Cryogenic-Safety-Manual.pdf

https://www.airgas.com/msds/001190.pdf

https://chemistry.berkeley.edu/research-safety/manual/section-7/cryogenic-liquids

https://www.co2meter.com/blogs/news/cryogenic-safety-working-near-cryogens