Why calibrate your CO2 sensor?

All carbon dioxide sensors need calibration. Depending on the application, this can be accomplished by calibrating the sensor to a known gas or using the automatic baseline calibration (ABC) method. Both have pros and cons you should know.

Most of our CO2 products use a non-dispersive infrared (NDIR) carbon dioxide sensor. These rely on an infrared light source and detector to measure the number of CO2 molecules in the sample gas between them. Over many years, both the light source and the detector deteriorate, resulting in slightly lower CO2 molecule counts. The industry calls this "drift".

What is Sensor Calibration?

To combat sensor drift, during calibration a sensor is exposed to one or more known gases with different amounts of CO2. The difference between the new reading and the original reading when the sensor was originally calibrated at the factory is stored in EPROM memory. This “offset” is then automatically added or subtracted to any subsequent readings taken by the sensor during use.

5 Types of Calibration Explained

1. Zero Point CO2 Sensor Calibration

Zero point calibration exposes the sensor to 100% nitrogen. Since 100% nitrogen means there is no CO2 present, the "zero point" can be updated in the sensor's internal memory. Resetting the zero point accounts for drift over time as the sensor ages.

The advantage of calibrating a CO2 sensor with 100% nitrogen is that it removes any deviation from the sensor's zero point (0% CO2) as it ages.

The disadvantage is that resetting the zero point, while important, is not complete factory calibration. For this, 2 point or span calibration is required.

2. Span CO2 Sensor Calibration

Span or 2-point calibration is performed at the lowest and highest gas levels for which the product is rated. Typically this is 0 ppm CO2 using 100% nitrogen, and a special gas mixture of both nitrogen and CO2 called calibration gas. Calibration gases are available from gas suppliers that contain 1,000 ppm CO2 up to 100% CO2.

Span calibration is performed at the factory immediately after a CO2 sensor is manufactured. It begins by exposing the sensor to a pure gas like 100% nitrogen. In the case of CO2 sensor calibration, the sensor’s reading for 0 ppm CO2 is recorded in the sensor’s memory.

Next, the sensor is exposed to the highest CO2 level for which the sensor is rated. For example, a 5% CO2 sensor would be calibrated with 5% CO2 with the balance of the gas nitrogen or air. After being exposed to the second known gas, the sensor's response is also recorded in the sensor's memory.

Once these 2 points are known, a linear response to the gas concentration between the 2 points can be assumed. This is known as a calibration curve and is shown in the image above in blue.

In theory, every gas level reading between the 2 calibration points should fall on the blue line. In reality, some gas sensors do not have a precise linear response to different amounts of the target gas. In these cases, the manufacturer may perform 4 or more point calibrations to create a curved response line instead of a straight line.

Once the calibration curve is known, a calculation is performed in the sensor's memory so that for every gas level measured, a sensor-specific reading can be computed. This calculation may be as simple as a slope intercept for a straight line, or in the case of a curve, a slope of a curve formula called the derivative.

During span calibration the zero point adjustment is also stored in the sensor's memory. The zero-point adjustment is what the sensor reads when it is exposed to the zero calibration gas. This difference (shown as the red line in the image) is saved as an offset to the sensor’s actual reading when exposed to 0% gas.

For example, If a CO2 sensor reads 10 ppm when exposed to 0 ppm CO2, an offset of “-10 ppm” is stored in the sensor’s memory and applied to all future readings.

Although the terms are used interchangeably, calibration is different from zero point adjustment. While zero point adjustment gives a more accurate sensor reading, span calibration is first required to match the sensor’s response curve to a known target gas.

While span calibration is always performed at the factory on every new sensor, in cases where precise accuracy is required, it may also be performed again in the field or by returning the sensor to the manufacturer.

The advantage of doing a span or 2-point calibration is that it is the closest you can get to the original factory calibration for a given sensor.

3. 3-Point CO2 Sensor Calibration

A variation on span calibration, 3-point calibration is performed at the lowest, midpoint and highest gas levels for which the product is rated. For CO2 safety Alarms calibration is performed at the 0.0% CO2 level, default alarm 1 level, and default alarm 2 level.

4. CO2 Sensor Calibration Using Fresh Air

Where maximum accuracy is less important than cost and simplicity, some CO2 sensors or devices can be calibrated using fresh air. Instead of calibrating at 0 ppm CO2 using 100% nitrogen, the sensor is calibrated at 400 ppm CO2, the agreed upon average for outdoor air.

For example, if a CO2 measurement device uses fresh air calibration, when the “calibrate” button is pressed on the device in fresh air, the sensor’s software assumes the current stable reading is 400 ppm CO2 and stores the difference between the current reading and the factory calibration as an offset value it uses until the next fresh air calibration

Fresh air calibration is best for sensors or CO2 monitors that are used to measure air quality, are portable, and can easily be taken outdoors.

For example, the CM-500 CO2 Handheld Gas Detector is designed to quickly spot-check CO2 levels up to 10,000 ppm. Because it is battery operated and portable, it can easily be calibrated outdoors.

Fresh air calibration is also used by many our Indoor Air Quality IAQ monitors. Models that run on battery power can easily be taken outside for fresh air calibration.

5. Automatic Background Calibration

Manufacturers of early CO2 sensors used in buildings to measure occupancy or indoor air quality levels realized the difficulty of calibrating wall-mounted units. Removing the units from the wall to bench calibrate was expensive, required trained staff, and with budget cuts, calibration schedules were often ignored.

To solve the problem of CO2 sensor calibration for IAQ, Senseair in Sweden developed Automatic Baseline Calibration (ABC). The theory behind ABC calibration is that for IAQ use, at some point each day a room is unoccupied. Eventually the CO2 level should return to 400 ppm, the same as outdoor air. By storing the lowest CO2 readings taken over time (typically several days) in the EPROM memory, an offset to 400 ppm could be calculated, then added or subtracted from the actual CO2 readings.

The advantage of Automatic Baseline Calibration is that the CO2 sensor is virtually self-calibrating over the life of the sensor. The disadvantage of the ABC algorithm is that it will not work properly if the sensor never "reads" 400 ppm fresh air. For example, ABC calibration would not work in an indoor livestock environment or an office building that was staffed 24/7.

ABC calibration is best suited for IAQ or any application where fresh air CO2 levels can be recorded by the sensor every few days. Otherwise, known gas (either nitrogen or fresh air) calibration should be used. Most of our sensors and some of our products have the ability to turn ABC on or off in the software, depending on how it will be used in an application.

Learn more about ABC calibration here.

Common Questions about CO2 Sensor Calibration

Do CO2 sensors need calibration?

Yes. Over time, all CO2 sensors need calibration to maintain accuracy. Even sensors that use ABC Calibration (see above) function best with regular calibration. Read the user's manual for the manufacturers recommended calibration interval.

How often should a CO2 sensor be calibrated?

The more accurate the CO2 reading required, the more often it should be calibrated. However, CO2Meter staff typically recommends customers to place their sensors or devices on a regular calibration cycle like their important devices and equipment.

For specific industries we recommend the following calibration cycles and methods:

- Scientific Experimentation – zero calibration before each test

- Safety – zero calibration at least annually

- Beverage/Restaurant - zero with nitrogen at least annually

- Indoor Greenhouse – zero with nitrogen after each growing cycle

- Manufacturing – zero with nitrogen at least annually

- Indoor Air Quality – ABC or fresh air as desired

These are general guidelines. Calibration schedules may also be dictated by experimental protocols or by particular industrial standards. Be sure to consult your specific sensor requirements for your application.

How do I know if my CO2 detector is bad?

The easiest way to test the sensor is to take your CO2 detector outdoors. Since fresh air has about 400 ppm carbon dioxide, your CO2 detector should measure the same.

Another quick test is to simply blow into the CO2 detectors' sensor opening. Human breath contains about 3,000 ppm CO2. The detector should quickly notice a rise in the CO2 level. Once you quit blowing on it, the detector should return to a normal CO2 level.

How long does a CO2 sensor last?

Most modern CO2 detectors use an NDIR sensor. With proper handling they should last between 10 and 15 years.

Note however, that low-cost CO2 meters may use electrochemical or VOC (volatile organic compound) sensors that only give an approximate CO2 level reading. These sensors are not accurate, and normally have a lifespan of 2 to 3 years.

In addition, some hand-held industrial safety monitors use electrochemical gas sensors also have a short lifespan. These meters have a "replace sensor" alarm to warn you when the sensor has reached its typical lifespan.

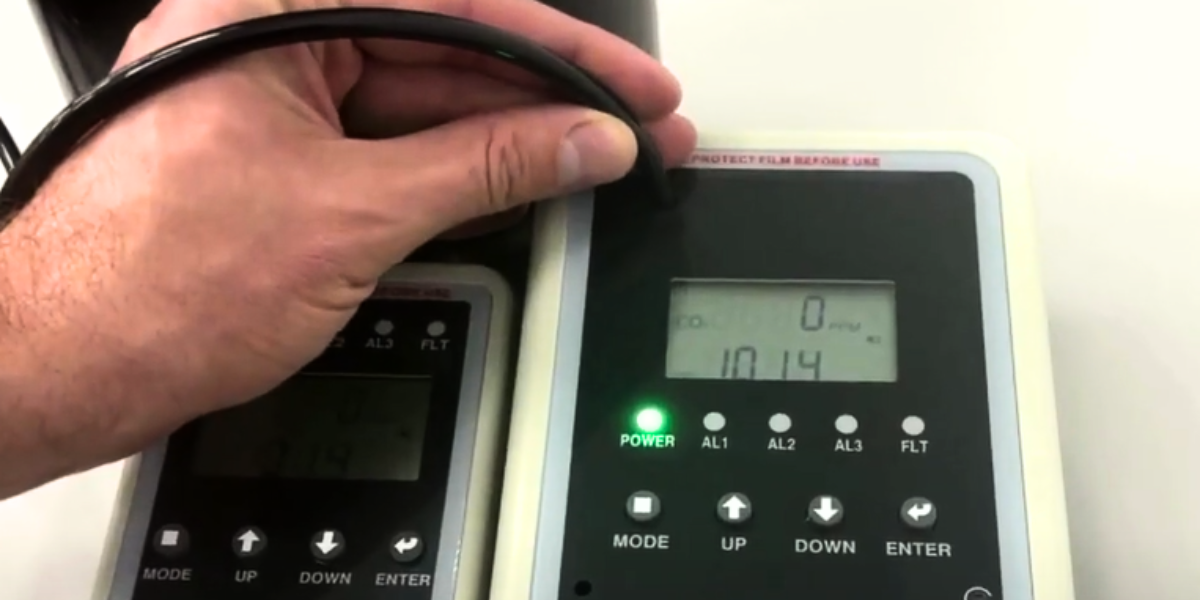

Can I calibrate my own gas detector?

Absolutely. Business safety department employees do it all the time. In general, you'll need a cylinder of calibration gas(s), a regulator a calibration bag and some tubing Simply reference your devices calibration procedure in the product manual for instructions. for your specific gas detector, monitor, or sensor.

The challenge is that in a business or factory if an employee is overcome by gas the lawyers will want to see a certificate of calibration. For this reason, many small businesses prefer to have their devices calibrated yearly by the supplier.

Annual Calibration Services for CO2Meter Fixed Gas Safety Systems

Overall, maintaining the accuracy and reliability of your CO2Meter fixed gas safety system is critical to ensuring compliance and protecting personnel from hazardous exposure. CO2Meter offers professional annual calibration services for all of our fixed gas detection safety systems, helping you stay aligned with OSHA, NFPA, and local fire code requirements.

Further, our expert gas safety technicians use certified calibration gas to verify sensor accuracy and make adjustments as needed, providing documentation for your safety records and inspections. Whether your system is installed in a restaurant, brewery, industrial fill plant or lab; our calibration services ensure continued peak performance and peace of mind. We offer on-site service options or fast turnaround with our mail-in program, depending on your needs and requirements.

To learn more about our CO2Meter gas equipment services, or to schedule a calibration today, click here to learn more.

For more information on specific calibration steps and procedures, you can also contact us.